Tin tức

Voltage stabilizer repair process

Understanding the Structure & Operating Principles, Common Issues & Solutions, Voltage stabilizer repair process,…

**************************************************** *****************

Mọi chi tiết xin liên hệ/For further details, please contact:

logo-hà lanVOLTAGE STABILIZER – PERFECT SOLUTION TO OVERWEAK POWER

Genuine 4 YEAR warranty

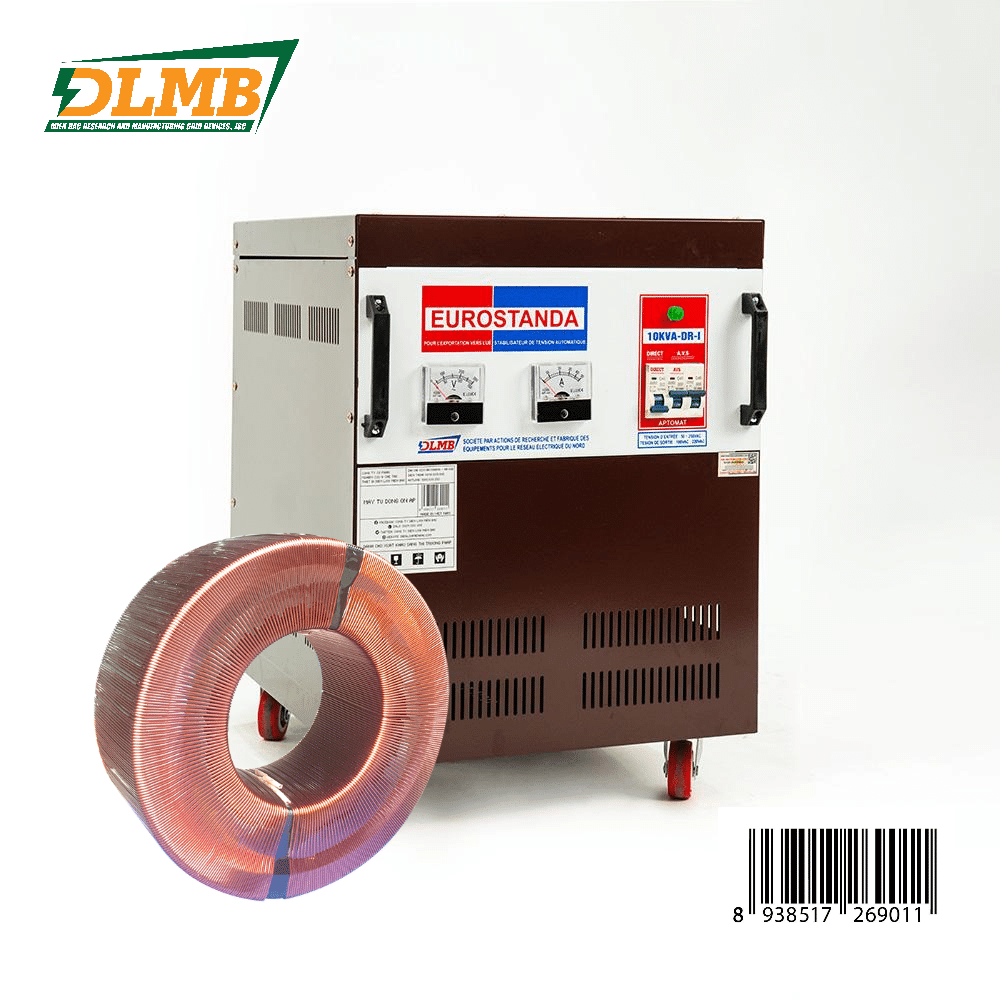

100% COPPER WIRE

Fast response speed

VOLTAGE STABILIZER – PERFECT SOLUTION TO REMEDY WEAK ELECTRICITY GENUINE WARRANTY 4 YEARS 100% COPPER WIRE Fast response speed

******************************* ******************* *******************

Hotline: 1900 633 550

Technical advice:(+84)932 203 866

Hotline: 1900 633 550 Technical advice:(+84)932 203 866

MIEN BAC RESEARCH AND MANUFACTURING GRID DEVICES JOINT STOCK COMPANY

Factory: AN KHANH Industrial Park – HANOI-VIETNAMESE

Factory: AN KHANH INDUSTRIAL PARK – HANOI-VIETNAMESE

Hotline : 1900 633 550

Fanpage: Hà Lan

Email: thietbidienluoimienbac@gmail.com; autovoltagestabilizer.vn@gmail.com

Xem sản phẩm khác/View other products here

Xem sản phẩm Haland 5kva tại đây

Xem sản phẩm Haland 7kva tại đây

Xem sản phẩm Haland 10kva tại đây

Xem sản phẩm Haland 15kva tại đây